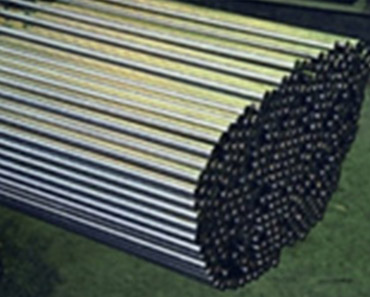

HIGH SPEED STEEL T42

High Speed Steel, T42 have been utilized as high performance cutting and moving instruments.

Devices basic application is a blend of high quality, wear resistance, high hardness together with durability, weakness resistance and warm resistance.

It is a high performance high speed steel with optimum cutting performance and also has a hot hardness with a good degree of toughness.

Chemical Composition

Chemical Element | Min | Max |

|---|---|---|

| Carbon, C | 1.15 | 1.30 |

| Manganese (Mn) | -.-- | 0.40 |

| Silicon (Si) | -.-- | 0.40 |

| Molybdenum, Mo | 3.00 | 4.00 |

| Chromium (Cr) | 3.80 | 4.50 |

| W | 9.00 | 11.00 |

| V | 3.00 | 3.70 |

| Co | 9.00 | 11.00 |

Physical Properties

Physical Property | Value |

|---|---|

| Density | 2.79 g/cm³ |

| Melting Point | 640 °C |

| Thermal Expansion | 23.10 x10^-6 /K |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 121-193 W/m.K |

Mechanical Properties

Mechanical Property | Value |

|---|---|

| Proof Stress | 270 MPa |

| Tensile Strength | 405 Min MPa |

| Elongation A5 | 12 Min % |

Features

Heat Treatment

Heat Treatment

Tempering

Tempering

Soft Annealing

Soft Annealing

Hardening

Hardening

Stress Relieving

Stress Relieving

Forging

Forging